With varied assets often spread across large areas, construction sites can be a tall order to manage, and pose a multitude of challenges to those who do. From heavy equipment and light vehicles to the workers themselves, there’s no shortage of moving pieces that need to be tracked and monitored. Inefficiencies in this respect are often the root cause of some of the most frequent headaches in this industry, especially those related to productivity, such as delays caused by misplaced equipment or absent workers, and high fuel costs from waste.

Boasting powerful capabilities for tracking the location, working hours, and conditions of both machinery and manpower, Navixy offers a fully-functional construction telematics solution. In this article, we’ll demonstrate how we’re equipped to solve your most pressing challenges, including support for alerts, reports, API, and other data visualizations tools, as well as numerous hardware options like hardwired, OBD, and battery GPS trackers, BLE sensors, and more.

Location tracking: maintain visibility over construction assets and employees

One of the most common challenges in construction is knowing exactly where your equipment and employees are. Completing projects on time means avoiding unnecessary delays, such as those caused by tracking down missing equipment. Whether equipment has been left at a previous jobsite or simply isn’t where it’s supposed to be, misplaced assets like bulldozers, backhoes, and dump trucks can bring progress to a grinding halt until they’re located. This is especially challenging when equipment is dispersed across a large area.

For example, one of the first major steps when constructing a building is laying the foundation. If the designated excavator can’t be located, then work will have to stop until it’s found, putting the project behind schedule when it’s barely begun. Such a holdup could impact the entire completion timeline, which may frustrate the client, increase labor costs, and even damage your reputation.

Alternatively, tools and other pieces of equipment can go missing if they’re kept in a vehicle that’s driven off site by an employee. If the individual fails to report to the jobsite, then the rest of the crew will have to scramble to find the right tools for the job. Once again, such a delay costs time and money, directly impacting your bottom line.

Reduce downtime and allocate resources efficiently with Navixy

To give you assurance about exactly where your assets are, Navixy offers a wide array of functionalities. Our numerous options for devices also allow you to track across asset classes, from vehicles and equipment to trailers and people.

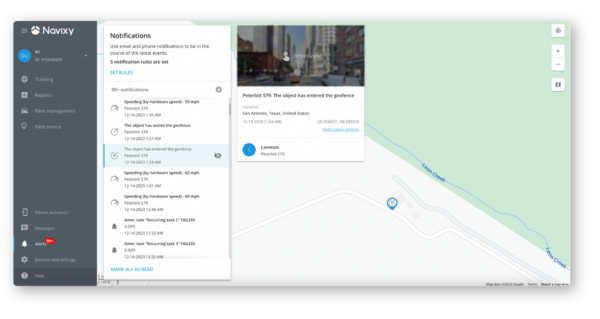

When you equip crucial pieces of equipment with durable, hardwired trackers, you always know the exact location of each asset in your fleet no matter the conditions. Battery- and solar-powered options give you even more flexibility for reliable, low-power tracking at remote sites. Meanwhile, convenient OBD trackers can be installed in vans, pickup trucks, and other light duty vehicles, so it’s easy to locate the right tools for the job at hand. And in the event of theft, geofence alerts let you know as soon as an asset has left its designated area, while live location updates help make the recovery process quicker and easier.

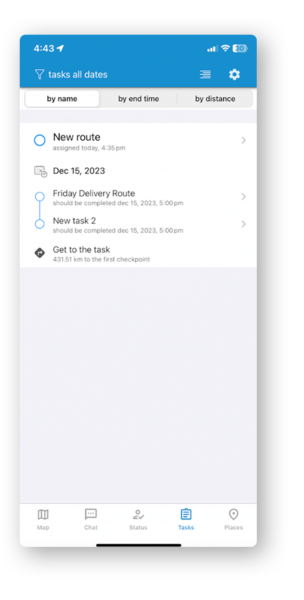

Along with vehicle tracking, Navixy also provides the X-GPS Tracker mobile app for powerful workforce management. This application not only keeps you in the loop regarding employee whereabouts, but also lets you see the current location of every team member to easily delegate the closest worker when a job opens up.

By reducing downtime, construction telematics tools from Navixy improve productivity, keep employees accountable, and make your operations more efficient. Moreover, you can feel confident about always having visibility of assets and employees to effectively place resources where they’re needed most and keep projects on time and under budget.

Working hours: track equipment usage and employee time

Along with location, construction companies also need to closely monitor the working hours of both their equipment and employees. Paramount for tracking billing, payroll, and other aspects related to usage, working hour data provides significant insight into your operational efficiency.

Equipment rental and leasing companies, for instance, need to know exactly how much a certain machine or apparatus was used to accurately bill their clients. Otherwise, the client could dispute the final invoice, or misuse the equipment and try to blame it on a latent problem. And speaking of disagreements, tracking employee working hours ensures that your payroll accurately reflects who performed a job and who did not. Ultimately, having a misleading or inaccurate idea of working hours can increase your total costs and hamper your profitability.

Navixy tools to enhance productivity and oversight

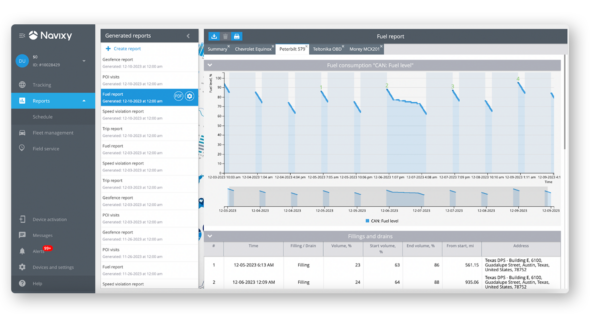

By effectively managing and allocating resources with Navixy, construction companies can transform the way they do business by identifying and eliminating waste. For instance, whether you rent machinery like tractors to other companies and use them in your own operations, you can use the engine hours report to know exactly when they’re idling, in motion, and turned off. This way, there’s no disputing whether or not a piece of equipment was used and for how long. Or, use this data to determine if a specific drill, truck, or rig is being used more or less than others.

For employees, our X-GPS mobile apps facilitate the management of remote teams with job check-ins, form submission, and additional field service tools. In addition to supporting accurate payroll numbers, these tools can also let you know if a work vehicle is at the correct site or not when used with geofences. For added oversight, create and assign jobs to specific employees to measure progress, while vehicle data and event notifications keep you in the loop to monitor conditions and support productivity.

Maintenance and fuel: avoid breakdowns and waste

Problems that stem from insufficient equipment maintenance are all-too-common sources of delay at construction sites and other industrial works. Therefore, keeping tabs on the condition of your heavy machinery and vehicles can prevent untimely breakdowns from bringing time-sensitive jobs to a halt.

Consider the following scenario. A dump truck is delivering a load of gravel to a site but when it arrives, it’s unable to lift the box and complete the delivery. Unbeknownst to the driver, the hydraulic lifts have gone too long without lubrication, causing a total system failure at a critical moment. Not only will this put the work on hold until the load can be manually deposited, but it may cause the company to lose their client’s future business and require an extremely costly repair.

Light duty vehicles, like vans and work trucks, also need to be carefully monitored and maintained. If workers are using these vehicles for personal errands, then they may need more frequent servicing, resulting in more down time and higher maintenance expenses. Moreover, the added fuel expense, especially if the vehicle is often left idling, can significantly increase your costs—especially in large fleets.

Prevent waste and breakdowns with Navixy fuel, driver behavior tracking

Keeping your trucks, cranes, pavers, loaders, and other equipment fully operational requires a proactive approach.

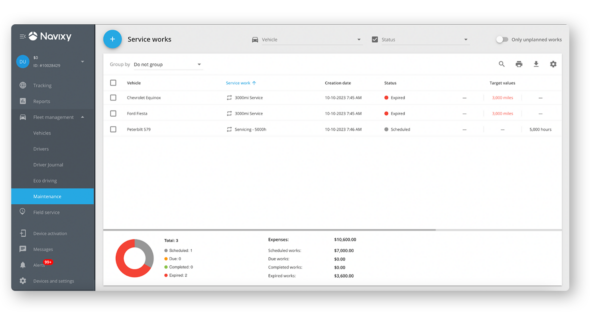

With the help of Navixy’s Maintenance tool, operators can monitor usage and easily determine which repairs are needed and when. Along with basing service intervals on either mileage or engine hours, managers can also set service alerts so they never miss preventative care. We support hardware trackers, as well as BLE sensors that monitor the ancillary movements of buckets and shovels. When sufficiently maintained, heavy machinery is less likely to break down unexpectedly or wear out prematurely, allowing you to maximize your investment and keep projects on schedule.

OBD and wired vehicle tracking devices, meanwhile, give you insight into how light duty vehicles are being used. These send data related to location and speed to the platform, allowing you to easily determine whether an employee is driving for business or personal reasons. Additional Navixy tools like driver logs and fuel sensors offer additional context for what drivers might be up to. Furthermore, fuel data and idle alerts let you know when and where fuel waste may be occurring, so you can correct the behavior, cut consumption, and decrease operation costs.

Navixy-powered construction telematics

From tracking heavy equipment to monitoring how employees use company vehicles, Navixy has the capabilities demanded by the construction industry to improve efficiency and productivity. More than dots on the map, we empower managers and integrators to build responsive telematics solutions that meet their specific needs. Ultimately, using our platform to track the location, working hours, and condition of construction resources frees you up to focus on meeting deadlines and increasing your bottom line.

Reach out today to hear more about the Navixy platform and our multitude of supported hardware options. We look forward to telling you more about how we’re prepared to help you promote efficiency and drive growth in your business.