Whether implemented in response to equipment misuse or lack of preventative maintenance, telematics can play a key role in monitoring heavy machinery. Challenges like premature wear of machinery, breakdowns that interrupt daily operations, and workplace accidents can all be addressed with this technology. All of these problems can result in costly repairs or replacements, lowering productivity and affecting profitability, in addition to putting the personnel who operate the machinery at risk.

iTrack, a GPS tracking company and Navixy partner located in Monterrey, Mexico, has used our platform to offer telematics solutions for the daily operations of heavy machinery. These solutions are based on numerous capabilities, including the automated use of device inputs and outputs, video telematics, real-time location, monitoring for maintenance, critical alerts, notifications in case of failure or incorrect use of machinery and your resources, and more.

Below we will explain this success story and how iTrack managed to obtain optimal results for different industries, such as diesel fuel dispensers and bucket trucks.

Solution for diesel dispensers

The first case was implemented together with Grupo Jibe, a construction company located in Coahuila. This company has four trucks that deliver diesel and oil to heavy machinery that do not leave the construction sites. Each dispatch truck carries around 7,500 liters (~2,000 gallons) of diesel.

Problem

For Grupo Jibe, it was impossible to track whether the fuel was only being delivered to the company's machinery, or if it was also delivered to personal or non-company cars.

Before working with iTrack, Grupo Jibe already used a flow meter to measure the liters that passed from the dispatcher to the machinery. However, they did not have the opportunity to see at what geographical point the fueling was carried out and exactly which machine was receiving it.

Solution

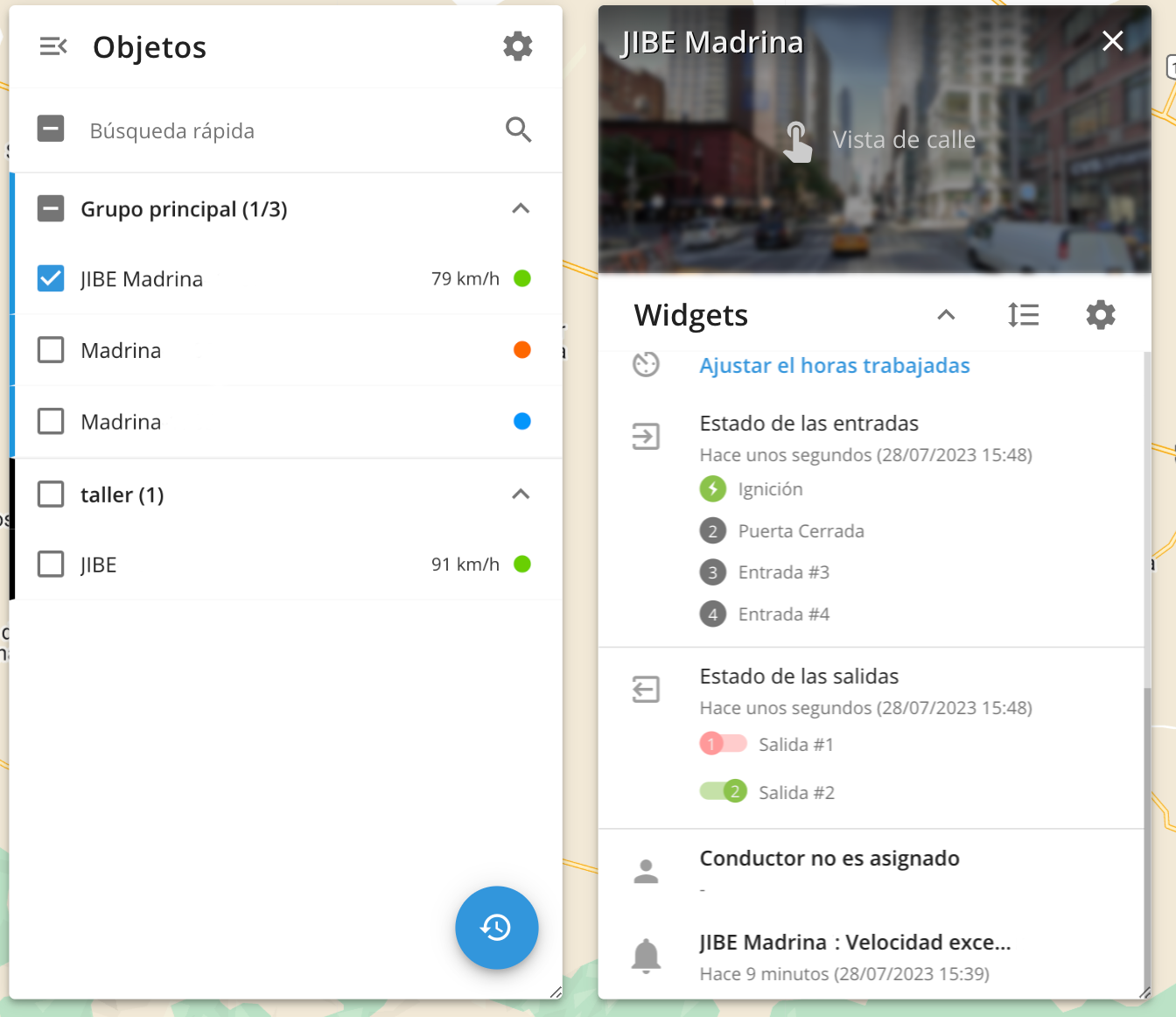

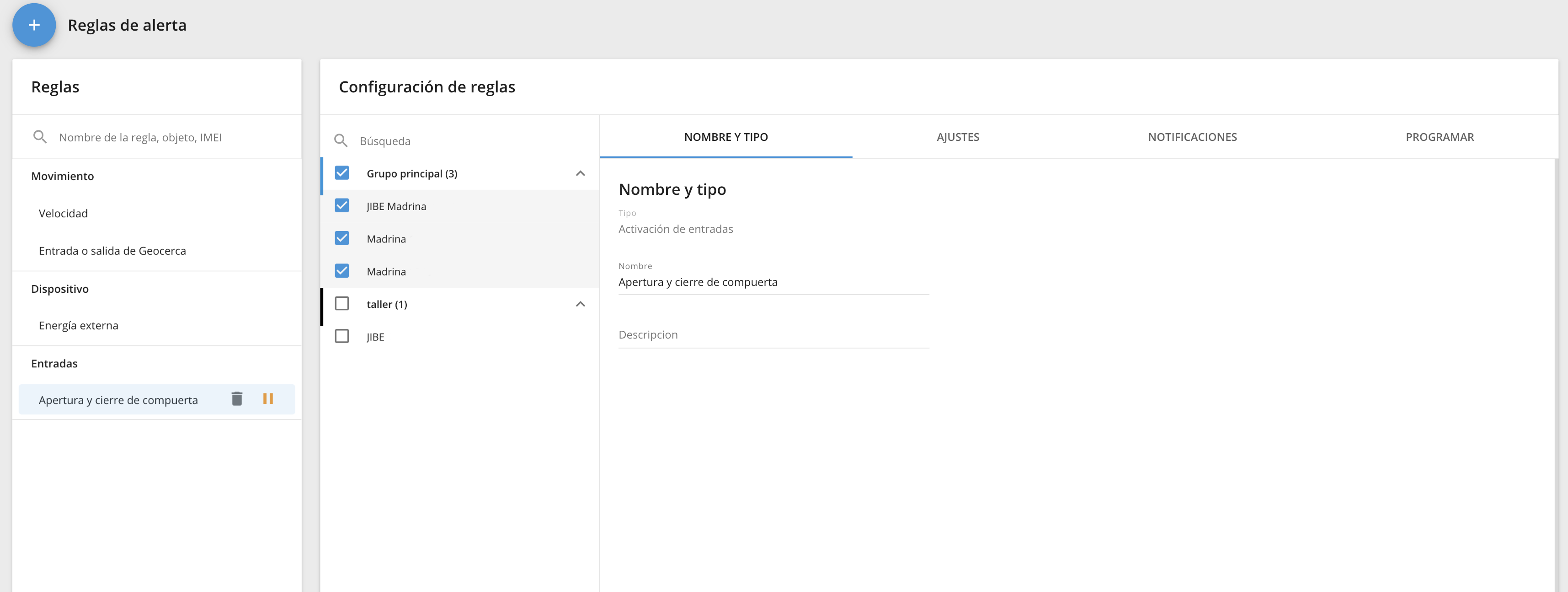

The diesel dispensing vehicle has a rear door that prohibits access to the loading guns and protects them during transport. This door opens with a hydraulic mechanism through a button located on the back of the dispenser. Company supervisors wanted to know when and where the lid was opened.

The theory is that the dispatcher could stop halfway and extract liters of diesel to sell later on his own, which would represent losses for the company.

Once the project was brought to iTrack, CTO Daniel Cossio proposed that the lid of the dispensing machine could be controlled through GPS device outputs. For this project they chose the Suntech ST600R that has four digital inputs and two outputs.

Stages of implementing telematics for heavy machinery

- Place a sensor to monitor the opening and closing of the door using the digital inputs of the device.

- Connect the output to the door opening mechanism. For this, they have installed a solenoid valve in the air line of the hydraulic system. The valve is controlled through the output of the GPS device.

- Install Howen MDVRs in the rear of the truck.

System use

When the truck goes out with diesel to construction sites, it locks the exit device to prevent the door from opening with the button on the back of the machine.

Although it’s difficult to do so, the door can be opened even when the opening mechanism is locked, so the door open alert is configured using the device inputs. That way, even if the driver tries to open the door when the mechanism is locked, the supervisor will be aware of the violation.

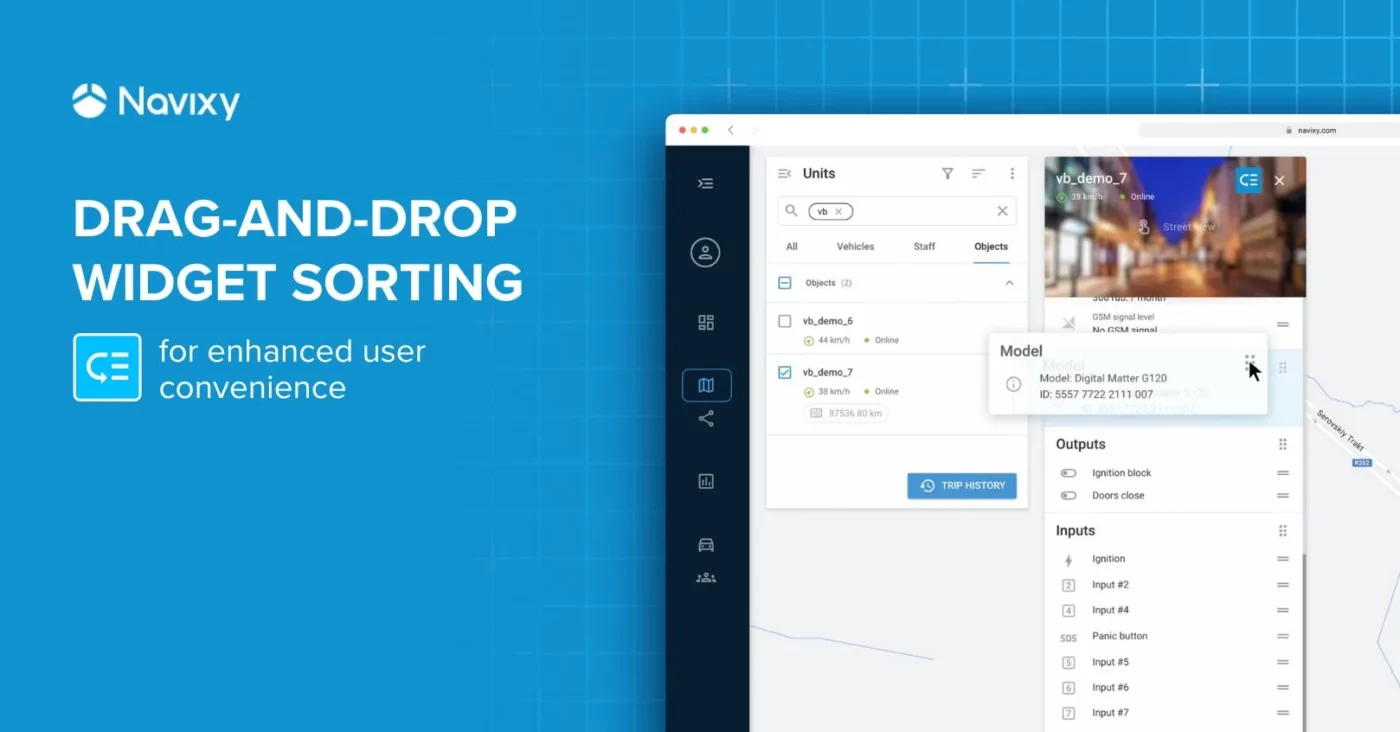

Once the fuel dispenser arrives at the destination, the team supervisor checks that the location of the machine is in the place where it must dispense the fuel. Likewise, they can connect to the MDVR installed at the back of the machine to better evaluate the environment and, if everything is good, unlock the door opening mechanism through the 'Outputs' widget on the platform. This prevents the delivery of diesel outside of construction sites, and allows the supervisor to see which machine was fueled and how much diesel was delivered.

Results

After four months of installing the telemetry system, theft of around 5% of the diesel could be detected thanks to the installed system.

This 5% of a 7,500 liter diesel tank is equivalent to 375 liters of diesel saved monthly, or $9,375 MXN ($516 USD) per month for each machine. Considering that the initial investment to install the entire complete system costs $17,200 MXN ($947 USD), the return on investment is made in two months. Thus, iTRack saves its client $95,300 MXN ($5,246 USD) per year for each machine.

Solution for bucket trucks

Problem

An electrical service company in Mexico detected that the bucket truck operators were driving while intoxicated, which resulted in the following problems:

•Accidents on the road

•Excessive speed

•Fines

•Damage to the platform

•Equipment downtime during repairs

The company shared the statistics that 70% of accidents involved drunk driving and excessive speed.

In addition, for safety compliance, the stabilizing supports must be opened before raising the boom. Only after that can the bucket be raised with a person inside.

What actually happened is that to save time, drivers were not opening the supports, causing the platform to tip over with the person on top. This accounted for another 20% of all accidents.

This caused injuries, damage to the machine, and safety problems in the workplace.

The last problem here was that the person in the bucket did not use the safety harness, which meant he could easily fall if the truck moved at all.

In total, the company has 1,000 cranes that need a telematics solution to prevent safety violations.

Solution

Similar to the previous case, iTrack mechatronic engineers implemented telematics for heavy machinery by using the digital inputs and outputs of GPS devices.

In addition, to ensure that the driver cannot drive while intoxicated, the iTrack engineers manufactured a breathalyzer using a 3D printer for the casing and Arduino for the programming. Every time a driver gets on the crane and wants to start the engine, he has to pass the test.

The breathalyzer device works by sending a signal to a control center developed by iTrack. The control center then sends it to the Suntech ST4305 GPS device, which in turn transmits the signal to the platform to notify the supervisor whether the driver passed or failed the test. Depending on the result, the control center sends the command to the device output to unlock or not unlock the ignition.

By using the device inputs, they were able to monitor the crane supports. They also installed an oil solenoid valve connected to the output of the Suntech device. When the inputs receive the information that the supports are engaged, the boom that raises the basket with the worker is unlocked through a command to the output connected to the solenoid valve. If the supports are not down, the GPS device output does not unlock the boom and there is no possibility of raising it.

Results

These telematics projects for heavy machinery successfully passed the testing phase and should soon be implemented by the electricity company. In its first stage, approximately 1,000 devices are planned to be implemented.

About iTrack

iTrack is a company dedicated to satellite tracking and vehicle location to provide fast and effective solutions for managing the use of its mobile units by organizing, controlling, and saving the work they do. They work with the highest quality and innovation in GPS, guaranteeing to optimize your resources, time, and activities.

The company has been in business since 2017 and is headquartered in Saltillo, with the development division in Torreón. They also have a mechatronic engineer in their hardware development design, as well as their own software developer.