The accuracy of fuel measurement is a key factor for efficiency and cost control in fleet management operations. One aspect that's often overlooked in ensuring this accuracy is the calibration table of fuel level sensors. This seemingly minute detail is a determining factor in the precision of fuel level measurements. Navixy's analytics reveal that improper calibration tables are a significant source of inaccuracies in fuel measurements, responsible for nearly 22% of all discrepancies. This highlights an important issue: high-precision fuel sensors might not perform effectively if they are paired with poorly prepared calibration tables during the installation of telematics systems. The dependability of fuel reports, an important tool for fleet managers, is greatly influenced by the quality of this calibration process.

For providers of telematics solutions, understanding and addressing this issue is key to maintaining the integrity of fuel level data. This post will explore the intricacies of the calibration process and discuss how Navixy's features and latest developments help in tackling this challenge.

What is a Fuel Calibration Table?

A fuel calibration table is an essential tool in the precise measurement of fuel levels within fleet management systems. This table acts as a translator, converting raw data from fuel level sensors into meaningful and actionable information about the actual fuel volume in a vehicle's tank.

How does it work? Essentially, the calibration table comprises a set of reference points that correlate specific sensor readings to actual fuel volumes. These reference points are derived from calibrating the sensor in various conditions and fuel levels. For instance, a certain sensor reading might correspond to a half-full tank, while another reading might indicate a nearly empty tank. By mapping these readings against real-world fuel levels, the calibration table enables the telematics system to interpret sensor data accurately.

A proper calibration table is pivotal to ensuring the accuracy of fuel measurements. If this calibration is not conducted correctly, the consequences can be significantly detrimental. Incorrect calibration leads to a misinterpretation of fuel levels, resulting in inaccurate fuel consumption data. This inaccuracy not only hampers the efficiency of fleet operations but also opens the door to potential fuel fraud. For example, a poorly calibrated sensor might report a full tank when in reality it is only three-quarters full, leading to erroneous billing or fuel usage reports. In scenarios where fuel costs constitute a major part of operational expenses, such inaccuracies can lead to substantial financial losses and operational inefficiencies.

Therefore, the calibration table is more than just a technical requirement; it is a crucial element that ensures the integrity and reliability of fuel monitoring systems. Proper calibration is imperative to maintain the accuracy of fuel data, which in turn supports effective decision-making and fraud prevention in fleet management.

Challenges in achieving accurate calibration: Human mistakes at the forefront

The path towards achieving precise calibration of fuel level sensors in fleet management is often hampered by an unexpected yet predominant factor: human error. Astonishingly, human mistakes account for a staggering 68% of calibration inaccuracies, far surpassing technical (26%) and environmental (4%) factors. This high incidence of human error unveils a critical challenge in sensor calibration – a lack of proper understanding, underestimation of the calibration table's importance, and inconsistent execution of the calibration process.

At the heart of this issue lies the need for comprehensive education and meticulous process management during the sensor installation phase. It's a common observation that even within organizations offering telematics solutions, using identical sensor equipment and software, there can be a drastic variance in accuracy. This inconsistency is primarily due to personnel not adhering strictly to the installation instructions, coupled with a lack of thorough checks on their work and the system's performance.

The majority of these errors stem from a fundamental gap in knowledge – many individuals involved in the installation process may not fully understand what fuel level sensor calibration entails. This lack of understanding leads to the underestimation of how critical a well-prepared calibration table is to the overall system's accuracy. Consequently, the calibration process may not be executed with the required diligence and precision. In scenarios where the calibration is treated as a routine, tick-box exercise rather than a critical procedure, the resulting inaccuracies can significantly impact the effectiveness of the fleet management system.

Furthermore, within organizations providing telematics solutions, there's a vital need for standardized protocols and regular training to ensure that all personnel are aligned with the best practices in sensor calibration. Regular audits and performance checks can also play a crucial role in identifying and rectifying these human errors, thereby enhancing the overall accuracy and reliability of the telematics systems.

Thus, while technical and environmental factors do influence sensor calibration, it's the human element that poses the greatest challenge. Addressing this through proper education, process standardization, and vigilant system monitoring is key to overcoming these hurdles and achieving optimal calibration accuracy in fleet management.

How Navixy helps avoid calibration table issues

Navixy, with its multi-year expertise in collaborating with fuel level sensor manufacturers, telematics professionals, and fleet managers, has developed a profound understanding of the challenges in fuel level measurements across various solution vendors, fleets, and environments. With this rich experience we provide effective solutions in addressing common issues encountered in fuel measurements. Earlier, we have detailed how Navixy tackles the issue of fuel sensor noise through the Fuel Sensor Quality Index(FSQI). Accuracy of the calibration tables is another significant aspect where Navixy makes a marked difference.

As the calibration table is a crucial component in ensuring accurate fuel level readings, Navixy's system is adept at automatically detecting common issues and anomalies that frequently arise in these tables. The common issues addressed are:

| Issue | Explanation and consequences |

|---|---|

| No data points | A fundamental issue arises when calibration tables lack any data points. This scenario essentially renders the table ineffective, as there is no reference for the system to interpret the sensor readings. Without these data points, the fuel measurement system cannot provide any reliable information, leading to a complete absence of actionable fuel level data. |

| Inadequately low number of data points | Calibration tables with an insufficient number of data points fail to capture the nuances of fuel level variations. This lack of granularity can lead to significant inaccuracies, as the system does not have enough reference points to accurately map sensor readings to actual fuel volumes. The result is a generalized, and often incorrect, interpretation of fuel levels, which can be misleading for fleet management decisions. |

| Incorrect data entries | Another prevalent issue is the entry of incorrect data into the calibration table. This is particularly problematic when the actual sensor values fall outside the lowest and highest entries in the table. In such cases, the system struggles to accurately gauge fuel levels, either overestimating or underestimating them. This misalignment between sensor readings and calibration data can lead to skewed fuel level reports, affecting the reliability of fuel consumption data and the detection of potential fuel fraud. |

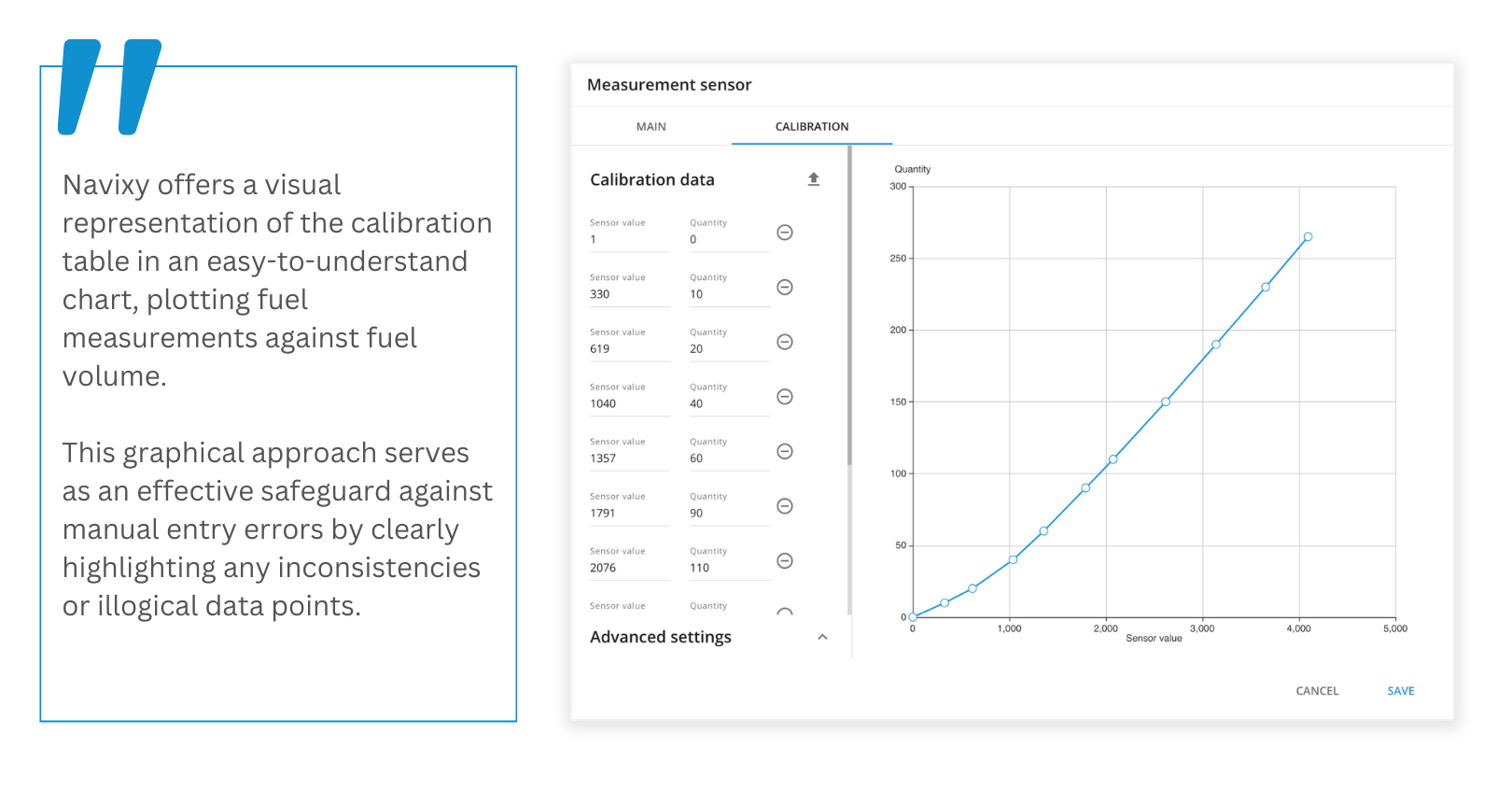

Navixy tackles the challenges in fuel sensor calibration with two key approaches to ensure accuracy and reliability in fuel level monitoring. Firstly, the platform provides a visual interpretation of the calibration table through an intuitive chart. This chart plots fuel measurements on the X-axis against fuel volume on the Y-axis. This visualization acts as a critical check against manual entry errors, as it clearly indicates if the data points are inconsistent or illogical. The graph should show a unidirectional trend, either consistently ascending or descending, ensuring that the calibration curve accurately reflects the relationship between sensor readings and fuel volume.

Secondly, with the recent update, the system now actively identifies common issues in calibration tables and conveys them to users through notifications within the fuel reports. These notifications are not merely alerts; they include detailed descriptions of the identified problems and provide practical recommendations for correction.

This dual approach — combining visual validation with intelligent notifications — equips telematics providers and fleet managers with the tools they need to maintain accurate and reliable calibration tables. These advanced software features not only improve the accuracy of fuel measurements but also play a crucial role in optimizing fleet costs.