Summary

- Reduce unplanned downtime by up to 40% through predictive maintenance alerts

- Cut maintenance costs by 15-20% with data-driven scheduling instead of fixed intervals

- Improve delivery reliability with real-time vehicle health monitoring

- Ensure regulatory compliance with automated diagnostic reporting

- Extend vehicle lifespan through optimized maintenance timing

Most fleet managers think they understand maintenance scheduling. Change the oil every 10,000 kilometers, rotate tires twice yearly, follow the manufacturer's service intervals — that simple. But conventional wisdom completely ignores the most important variable: where and how those vehicles actually operate.

A delivery van navigating the pothole-riddled streets of Bucharest faces entirely different stresses than one cruising the highways between Dubai and Abu Dhabi. Yet traditional fleet maintenance schedules treat them identically. The result? You're either over-servicing vehicles that don't need it or missing critical warning signs in ones that do.

The companies winning in last mile fleet management have quietly abandoned calendar-based maintenance entirely. They're reading their vehicles like diagnostic manuals, interpreting data patterns that predict problems weeks before they manifest. While competitors scramble with emergency repairs, smart operators schedule maintenance during slow periods and keep fleets operational when demand peaks. They do this with the help of telematics platforms like Navixy.

What is the recommended fleet maintenance schedule approach?

Traditional maintenance wisdom says: service every X kilometers or Y months, whichever comes first. This approach treats a van making 200 short urban deliveries exactly the same as one running long highway routes between cities.

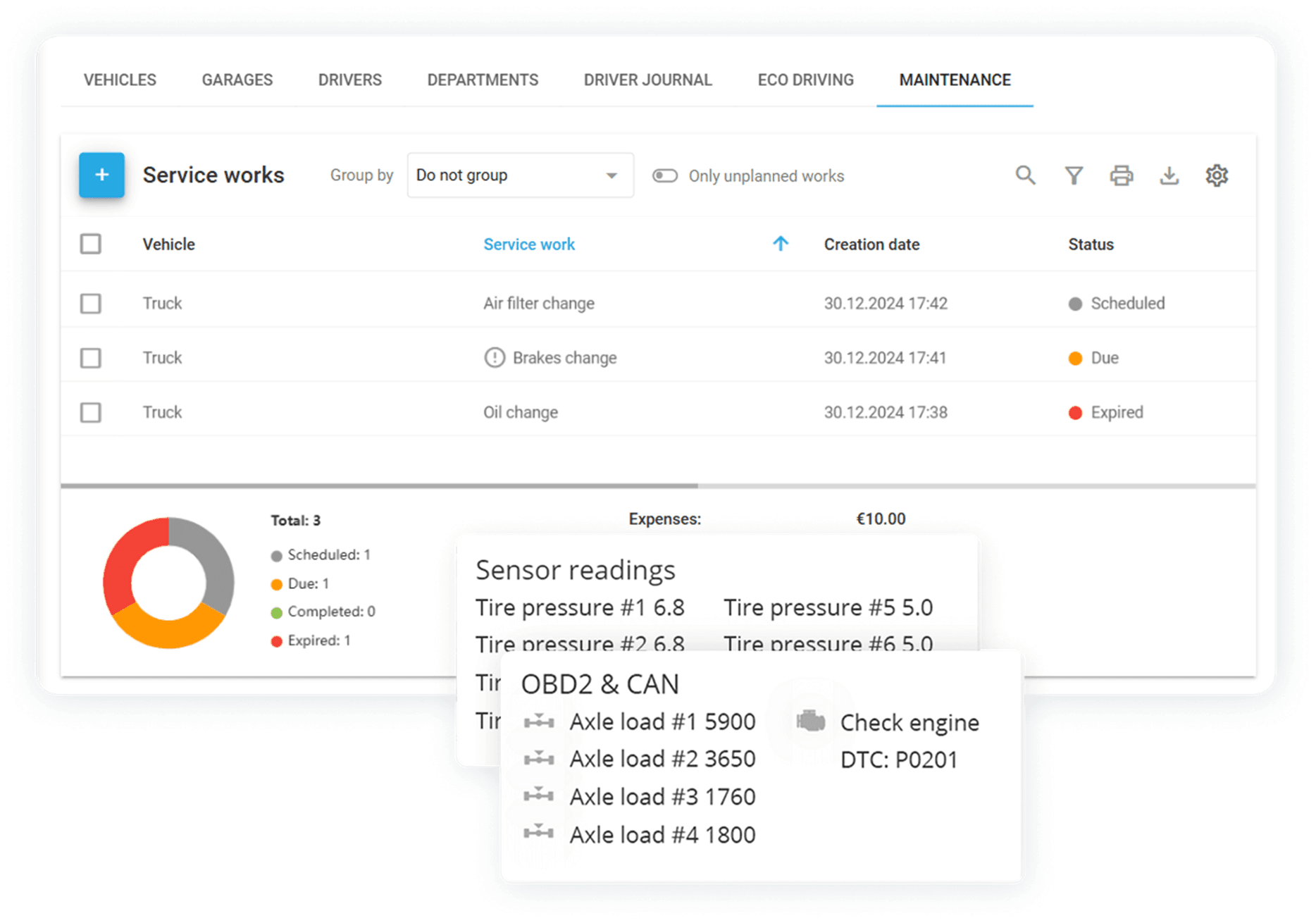

With Navixy, every customer can set up their own maintenance schedule. With the help of Navixy IoT Logic, it’s possible to implement smart, preventive fleet maintenance strategies. Instead of relying solely on calendar dates, a company can plan vehicle service based on actual condition data.

For example, when diagnostic monitoring detects rising engine temperatures during stop-and-go traffic, the system immediately flags the cooling system for inspection — rather than waiting for the next scheduled interval. One such case study is described in a recent blog post.

Real-time vehicle diagnostics through Navixy platform capabilities

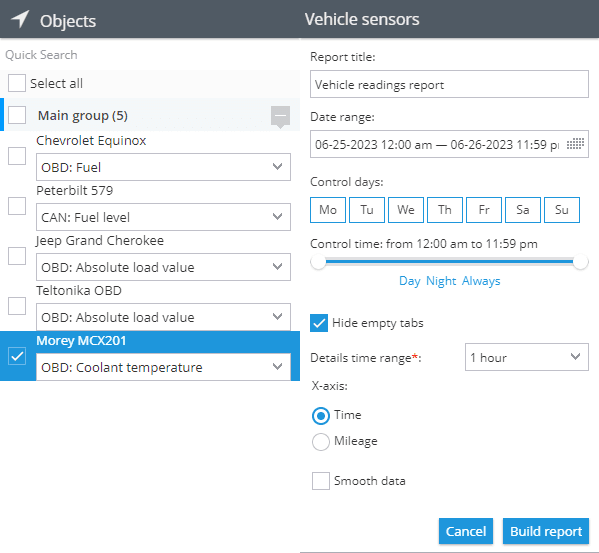

Navixy's platform connects through OBD-II integration to monitor engine load patterns, brake system performance, and dozens of diagnostic parameters continuously. The system tracks coolant temperature, oil pressure, transmission behavior, and fuel efficiency patterns across different driving conditions through compatible GPS devices.

Raw data becomes actionable when algorithms correlate seemingly unrelated signals. Declining fuel efficiency combined with increasing engine temperatures might indicate air filter problems. Harsh braking events clustered around specific routes could predict accelerated brake pad wear in certain traffic patterns. The system learns these correlations and predicts maintenance needs before traditional symptoms appear.

Why it matters?

Regional traffic patterns create unique maintenance challenges. Urban centers with narrow streets and heavy pedestrian traffic generate more harsh braking events compared to suburban routes. Rotating vehicles between different operational zones helps balance wear patterns while extending component life across the entire fleet.

Engine health monitoring and fault code analysis

Navixy's diagnostic integration captures engine fault codes immediately when they occur, not weeks later during scheduled service appointments. When intermittent problems trigger diagnostic trouble codes, the platform logs frequency, operating conditions, and correlations with other symptoms. This data helps mechanics diagnose problems faster and more accurately.

Traditional maintenance often ignores intermittent fault codes until they become consistent problems requiring emergency attention. Modern predictive maintenance flags these patterns early, enabling spark plug replacement during routine service rather than emergency roadside repairs months later.

How do you plan fleet maintenance effectively?

Effective planning requires integration between maintenance prediction, route optimization, and workforce scheduling. Traditional approaches treat these as separate functions, leading to vehicles needing service during peak delivery periods or maintenance appointments requiring expensive deadhead miles.

When Navixy detects vehicles approaching maintenance windows, it adjusts assignments automatically through API integrations. The platform's workforce management capabilities gradually shift maintenance-due vehicles to shorter routes ending near service facilities. Dispatchers receive automated recommendations assigning these vehicles to local deliveries while healthier vehicles handle longer routes.

This integration approach reduces deadhead miles to maintenance appointments significantly while ensuring vehicles receive service before problems develop into failures.

GPS fleet tracking vehicle maintenance scheduling benefits

Location data completely transforms maintenance decisions. Vehicles operating in dusty construction zones require more frequent air filter changes. Those navigating flood-prone areas during rainy seasons need additional undercarriage inspections. Urban delivery vehicles experience different stress patterns than rural route vehicles, influencing everything from brake wear to cooling system performance.

With Navixy IoT Logic, fleets can configure the necessary alerts and respond to vehicle conditions in real time, ensuring timely maintenance and reducing the risk of costly breakdowns.

Measuring business impact through vehicle health reports

Vehicle health reports evolved from static snapshots to dynamic, continuously updated fleet condition pictures. Navixy's dashboard displays each vehicle's health score, trending metrics, and predictive maintenance recommendations in real time through customizable interfaces.

These reports connect vehicle condition directly to business outcomes. Declining health scores indicate increased breakdown risk during peak delivery periods. Rising maintenance costs for specific vehicles highlight replacement decisions before they become emergency situations requiring immediate action.

Real-world ROI from predictive maintenance

Industry studies consistently show fleets implementing comprehensive vehicle health monitoring achieve 30-40% reductions in unplanned downtime, translating directly to improved delivery performance and reduced operational costs.

Montenegro's AVITA taxi service provides a concrete example of Navixy's maintenance capabilities in action. The platform captures EV-specific parameters directly from vehicle systems, providing live data for more efficient fleet management and improved customer experience. What was once a source of operational headaches became a competitive advantage, with uptime and reliability metrics surpassing even their previous combustion fleet.

Last-mile fleet management solutions that scale

Scalability maintains effectiveness as complexity grows. Small fleets manage maintenance through personal relationships with mechanics and intuitive vehicle knowledge. Coordinating service for 50, 100, or 500 vehicles across multiple locations requires automated decision-making processes.

Navixy scales naturally by automating maintenance decisions. Whether managing 10 vehicles locally or 200 across Eastern Europe, the system applies consistent predictive algorithms and optimization logic. Regional managers receive localized reports while headquarters maintains fleet-wide visibility through unified dashboards.

Implementation and regional compliance considerations

Successful predictive maintenance implementations begin with clear baseline measurements and gradual feature adoption. Fleet management for last mile delivery works optimally when maintenance scheduling integrates smoothly with existing operational workflows rather than replacing them overnight.

Regional markets present unique challenges:

- Eastern European fleets crossing multiple borders need maintenance records satisfying various national regulations.

- Middle Eastern operations deal with extreme temperatures and dust accelerating component wear.

- Latin American fleets face security concerns affecting maintenance scheduling, servicing vehicles in certain areas requires additional precautions.

Navixy addresses regional requirements through configurable compliance modules and localized reporting features. The reports can be exported in required formats for regulatory inspections while adapting schedules for local operating conditions.

Ready to transform your maintenance approach?

Navixy's predictive maintenance platform provides real-time vehicle diagnostics and intelligent scheduling tools your last mile operation needs. Request a demo to see how data-driven maintenance scheduling can improve your fleet readiness.

Frequently asked questions

How often should fleet vehicles be serviced for optimal performance?

Service frequency should depend on actual vehicle condition and usage patterns rather than arbitrary calendar intervals. In Navixy you can analyze real-time diagnostic data, operating conditions, and wear patterns to recommend optimal maintenance timing for each vehicle. Explore demo to try maintenance functionality.

What role does fleet readiness play in last-mile delivery success?

Fleet readiness directly determines delivery reliability, customer satisfaction, and operational profitability. Unplanned vehicle breakdowns create cascading problems: emergency repairs, missed delivery windows, route reassignments, and customer service issues. Effective fleet maintenance scheduling ensures vehicles stay operational during peak demand periods when they generate maximum value.

What is the biggest issue with last mile delivery operations today?

While route optimization and customer expectations receive attention, vehicle reliability remains the fundamental challenge that can derail operational plans. Advanced routing algorithms and real-time customer communication become worthless when vehicles break down unexpectedly. Proactive maintenance scheduling addresses this core vulnerability by preventing failures before they impact service delivery.

How do GPS tracking benefits extend to maintenance scheduling?

GPS data reveals operating patterns that traditional maintenance schedules ignore completely. In Navixy IoT Logic you can set correlation between location data with vehicle diagnostics to customize maintenance schedules based on actual operating environments rather than generic manufacturer recommendations.

Can maintenance scheduling really reduce fleet operating costs?

Predictive maintenance typically reduces total operating costs by 15-20% through multiple channels. Direct savings come from preventing expensive emergency repairs and reducing unnecessary scheduled services. Indirect benefits include improved fuel efficiency from well-maintained engines, extended vehicle lifespan, reduced insurance costs from fewer accidents, and increased revenue from better delivery reliability during peak periods.